Peru PV4&PV6 PPGI GI roofing sheet roll forming machine

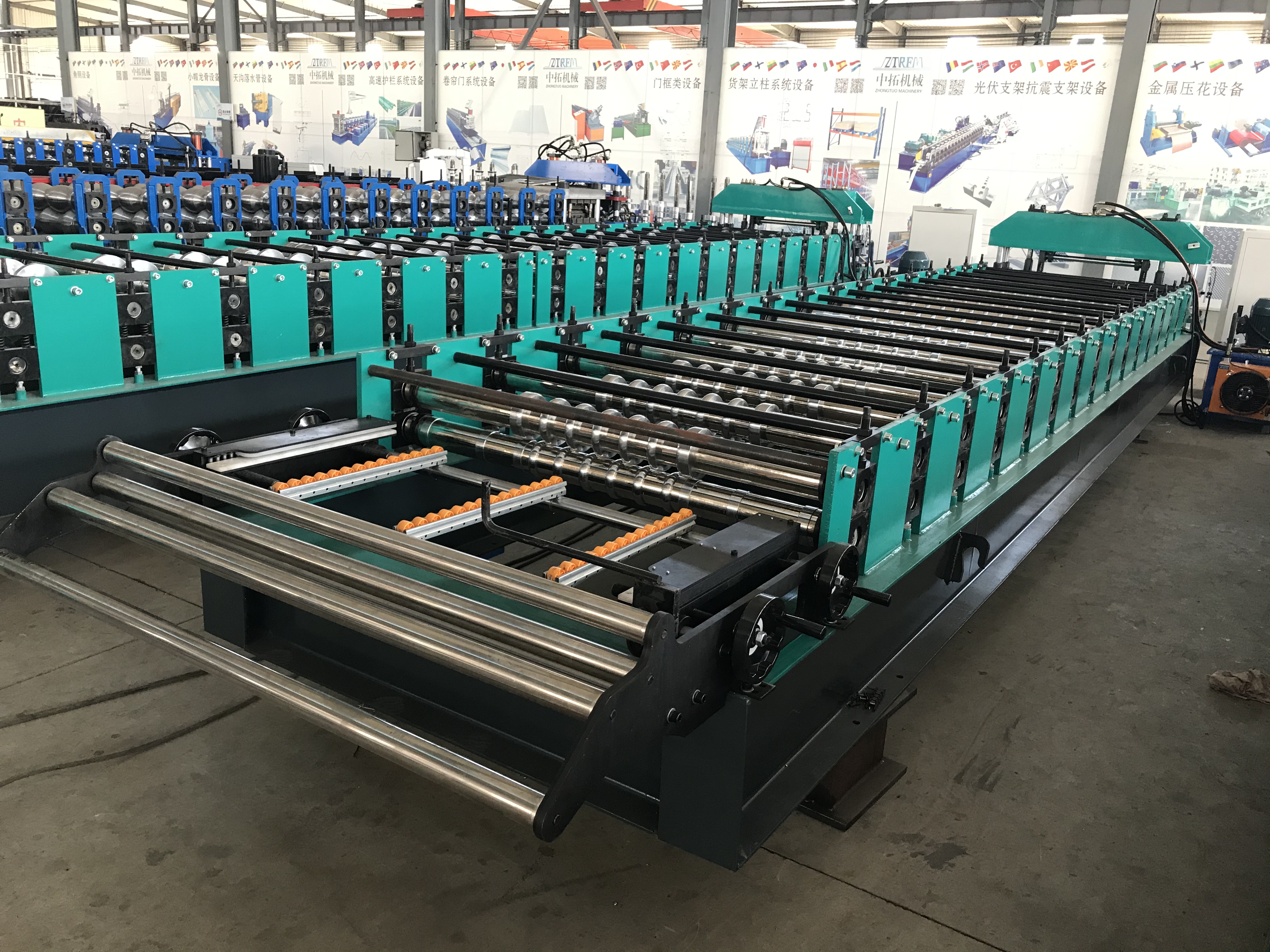

Zhongtuo's roofing sheet-making machine pays more attention to detail improvement. Now roofing sheets making machine has introduced the latest stainless steel roller feeding device, equipped with manual puller, which can save material and facilitate cutting, of course, if you want to improve the work efficiency, hydraulic front shear and electric shear are also very popular; the transmission chain has increased the tensioning device, which can regulate the chain's tensioning state and prolong the service life of the chain.

The forming part of the machine we have integral forming and split forming, two categories. According to the customer's version, wave height to customize, the basic structure of the machine has a middle plate chain and plate gear box, a guide column with 3 kinds of structures, to meet all your needs

Machine frame | Cast iron archway ,high precision and better stability |

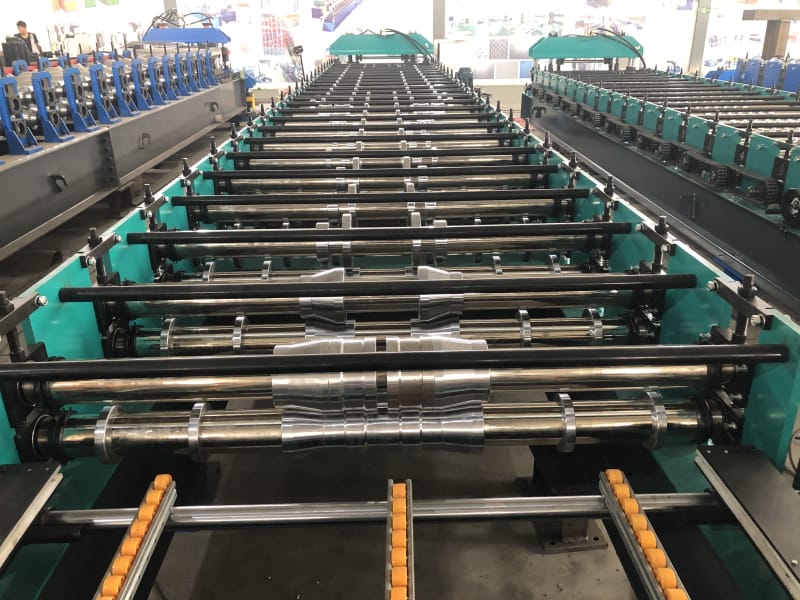

Material of rollers | High grade 45# forged steel Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life |

Forming stations | 20Rows; Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision |

Transmission way | Double chains;Gearboxs |

Cutting blade material | Gcr12 quenched treatment |

voltage | As Customized |