The double-layer roofing sheet machine is composed of upper and lower layers, and can flexibly choose different shapes (such as corrugated, trapezoidal, flat plate, etc.), adapting to the tough lines of industrial plants and the modern aesthetics of commercial buildings. Its appearance is highly optional with rich material colors. In addition to conventional blue, red, and gray, special colors like ivory white and champagne gold can be customized. Moreover, digital printing technology can present realistic textures such as imitation wood grain and sandstone grain. Both color saturation and texture can be precisely customized according to architectural styles and customer needs, meeting the design requirements of building exteriors and clients.

The upper and lower steel plates of double-layer roof tile making machine are bonded by composite technology, making them sturdier than single-layer ones. This structure boasts strong bending resistance, remaining intact even in strong winds, heavy snow, or rain. It's ideal for typhoon-prone or snowy areas, as it firmly supports the roof, resists deformation, and provides better protection for buildings.

Surface Coating Waterproof Performance:

The surface of color-coated steel plates is smooth, allowing rainwater to flow smoothly without easy water accumulation, which further enhances the waterproof performance.

Customizable Rows According to Customer Needs:

The double-layer roof tile making machine can be customized in the number of rows without requiring uniformity. For example, more rows can be laid in areas needing enhanced protection, while fewer rows can be used to save materials in other areas. Such flexible adjustments can adapt to the size and functional requirements of different buildings, making the laying more suitable for practical scenarios.

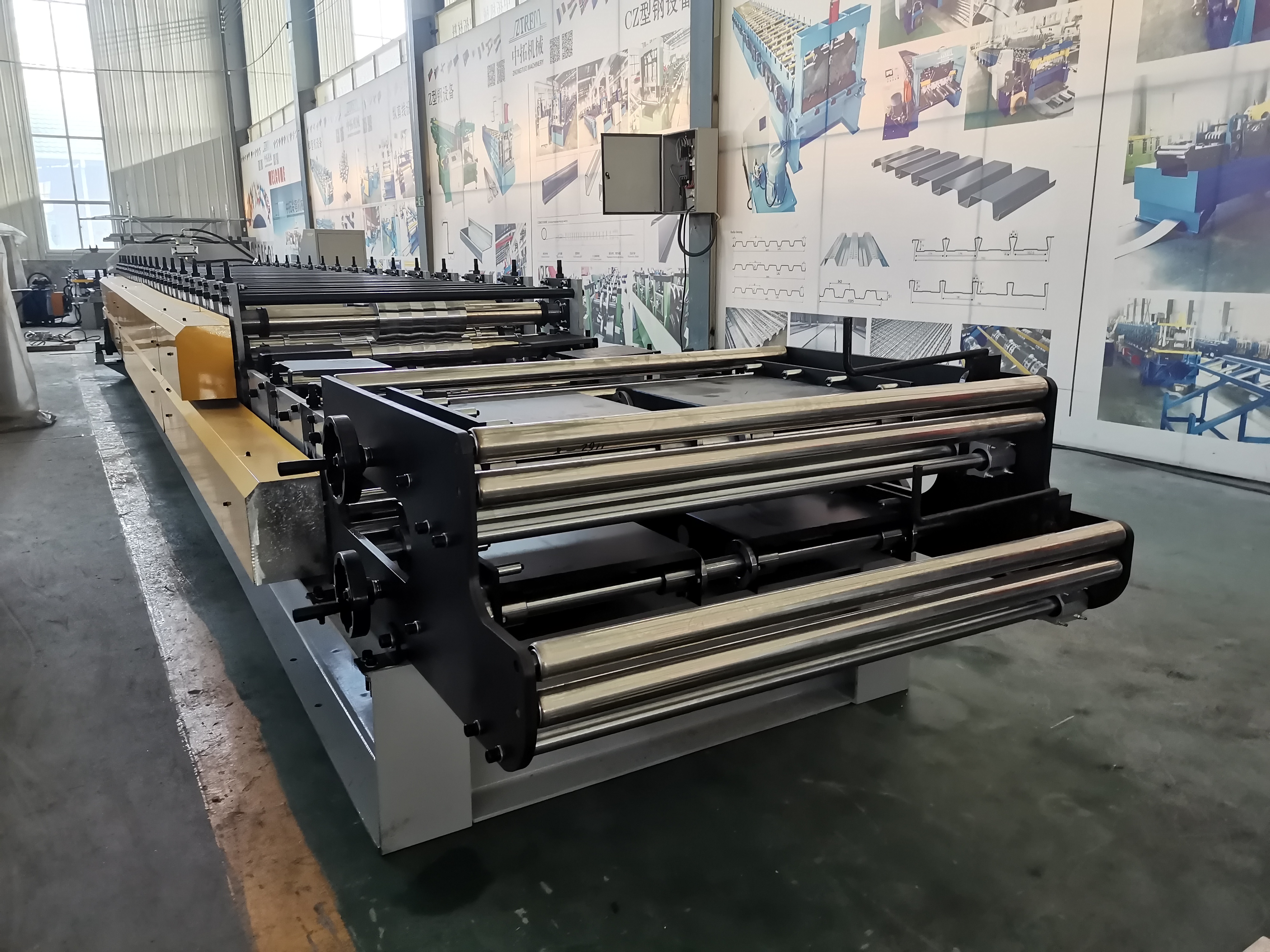

Middle Plate Structural Design of Double-Layer Roof Sheet Rool forming machine

The double-layer color steel tiles adopt a middle plate structural design, which is like installing a "stabilizer" for machine operation. The middle plate evenly distributes the force, keeping the machine stable during high-frequency vibration and continuous operation, and effectively reducing shaking caused by resonance. Meanwhile, the middle plate enhances the overall rigidity, firmly maintaining the material shape even in complex environments or under high-intensity use, greatly reducing the risk of twisting and deformation, and prolonging the service life of color steel tiles.

Shearing Method of Stop-Machine Cutting for Double-Layer Roofing sheet rool forming machine:

The double-layer roofing sheet machine adopt the stop-machine cutting method. When cutting the color steel tiles, the main forming machine will automatically stop operating to ensure the plate is in a stationary state. This shearing method can effectively avoid size deviation and cut burrs caused by plate movement, ensuring the cutting accuracy and cross-sectional flatness of each section of color steel tiles. Combined with a high-precision positioning device, error control can be achieved, providing high-quality and standardized building materials for subsequent installation and construction.