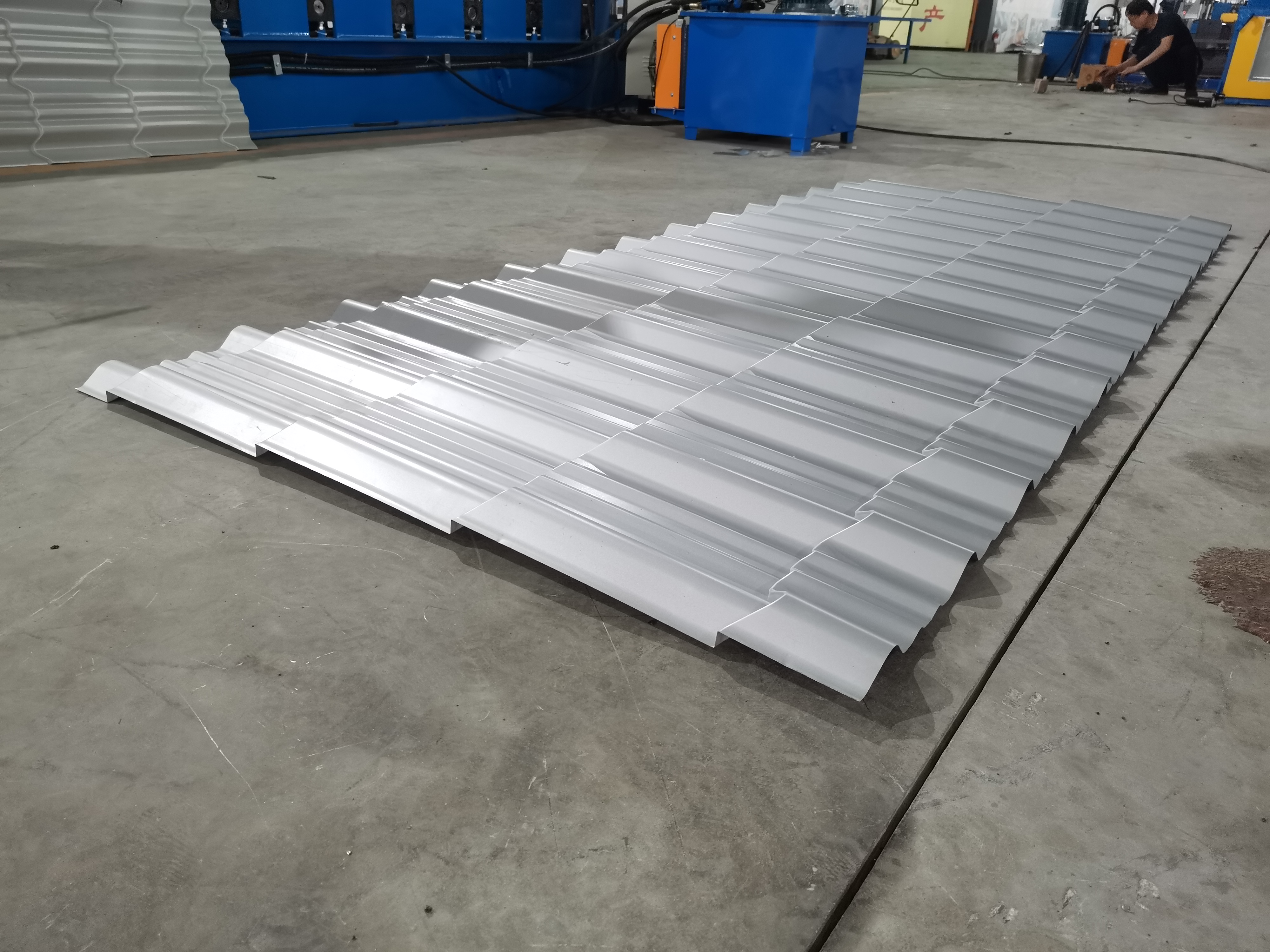

Glazed tile and corrugated sheet roofing sheet machine

The double layer roofing sheet machine is an advanced manufacturing system designed to produce high-quality, insulated metal roofing panels. This automated equipment processes metal coils through a series of rollers to form two-layer sheets with an air gap, enhancing thermal and structural performance. Commonly used in industrial, commercial, and agricultural buildings, these machines support various profiles, including trapezoidal and corrugated designs.

Advantages:

Save space – One machine can enough customers' two production pattern needs, save factory space.

Thermal Insulation – The air gap between layers reduces heat transfer, improving energy efficiency by up to 30%.

High Production Speed – Automated operation allows speeds of 15-25 meters per minute, ensuring fast output.

Material Efficiency – Eliminates the need for separate insulation layers, cutting material costs by 15-20%.

Superior Weather Resistance – Interlocking seams provide excellent waterproofing (IPX4 standard) and wind resistance (up to 3.5 kPa).

Durability – Double-layer construction increases load-bearing capacity, extending service life beyond 25 years.

Quick Installation – Pre-formed panels reduce on-site labor by 40% compared to traditional roofing.

Eco-Friendly – Uses 100% recyclable steel with minimal waste (<1.5%).

Modern models feature PLC controls for precise thickness adjustment (0.3-0.8mm) and tool-free profile switching (<5 minutes). Ideal for warehouses, factories, and stadiums, this machine delivers cost-effective, long-lasting roofing solutions.

Machine introduction

1.Feeding device

1. Hand wheels on both sides can be used to adjust the feeding width.

2. Four stainless rollers can make the material go into the machine smoothly and prevent the scartch on the material surface.

3. There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

2. Main rool forming machine

Main roll forming machine | |

Machine frame

| 350mm H beam structure, with 18mm welded steel middle support plate. |

Material of rollers

| High grade 45# forged steel |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Forming stations | Upper layer 14 rows ;Down layer 16 rows |

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

Diameter of shafts | Φ80mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 0-15m/min |

voltage | 380V/50HZ/3P (as requested) |

Transmission way | By 1 inch chain (double chains) |

Main motor | 5.5kw |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | hydraulic post cutting |

Driving method | By pillar type Cylinder |

3. Machine base frame

1. Enhanced Structural Reinforcement:

The machine base frame incorporates strategically positioned diagonal cross-bracing systems. This engineered design significantly improves torsional rigidity and load distribution, effectively minimizing frame deflection during high-speed operation. The triangulation principle created by these braces transforms static forces into axial loads along the brace members, resulting in exceptional vibration resistance and structural integrity. This ensures consistent precision alignment of rollers even under maximum production loads, directly contributing to long-term dimensional accuracy and reduced maintenance requirements.

2. Precision Manufacturing & Durability:

Following full assembly welding, the entire frame undergoes controlled vibration stress relief (VSR) treatment. This critical process eliminates residual stresses within welded joints, preventing future distortion or warping. Subsequently, the frame is precision-machined on large-scale CNC planers, achieving a flatness tolerance within 0.1mm/m² across all mounting surfaces. This guarantees perfect horizontality and uniform load-bearing capability. Crucially, the center support plate features a 20mm-thick high-tensile steel construction — substantially thicker than standard industrial plates — providing superior resistance to cyclic fatigue and permanent deformation. Combined, these processes deliver an exceptionally rigid foundation that maintains calibration integrity throughout heavy-duty, continuous production cycles.

4. Shearing system

Cutting blade material | Gcr12 quenched treatment |

Cutting type | hydraulic post cutting |

Driving method | By pillar type Cylinder |

Furthermore, we can guarantee that the finished product will have a perfectly formed surface, with no scratches on the sheet metal and no wrinkles in the forming results. Whether for personal use or for selling finished products, Zhongtuo's machines are the best choice.

More details welcome to find Daniel