Glazed Roofing Sheet Machine

Zhongtuo's glazed roofing sheet machine specializes in producing durable, aesthetically pleasing roofing tiles from steel or aluminum coils. The automated process includes:

Uncoiling & Leveling – Feeds and flattens metal coils for consistent material input.

Pre-Punching – Creates drainage holes or connection points if required.

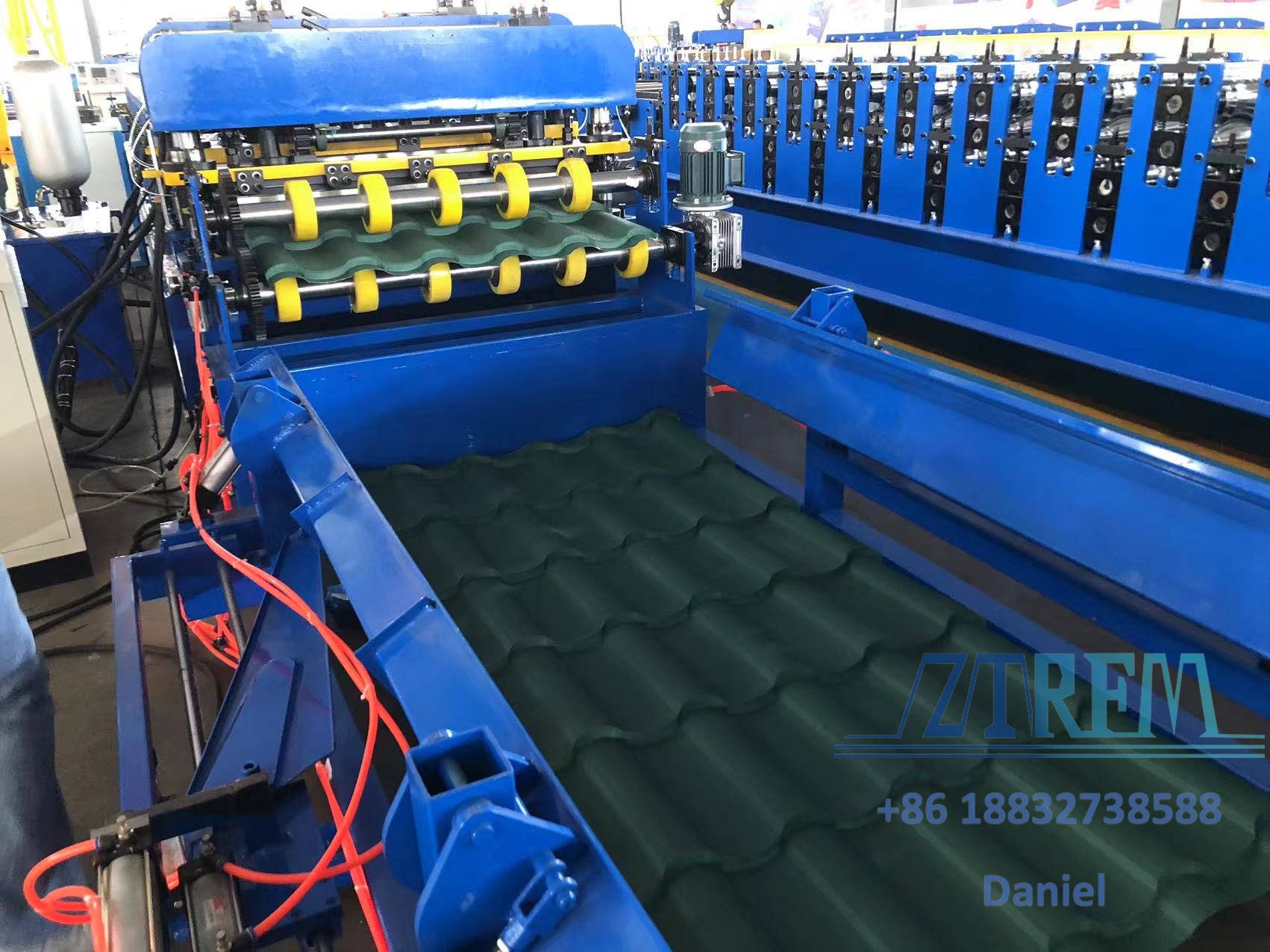

Roll Forming – Shapes the metal into tile profiles (e.g., Roman, Spanish styles) via sequential rollers.

Cutting – Precision hydraulic or servo cutting to specified lengths.

Stacking/Packaging – Automated output for efficient logistics.

Advantages

High Efficiency – Produces 15–30 tiles/minute, ideal for large-scale projects.

Material Versatility – Handles galvanized steel, aluminum, or prepainted coils (0.3–1.2mm thickness).

Low Maintenance – Robust design with wear-resistant rollers and minimal downtime.

Energy Saving – Optimized motor systems reduce power consumption by ~20% vs. conventional models.

Customization – Adjustable molds support diverse tile patterns and dimensions.

Durability – Anti-rust coatings and UV-resistant finishes extend product lifespan.

Machine working flow chat like this :

Now, I will show our Zhongtuo glazed roof tile making machine different parts details :

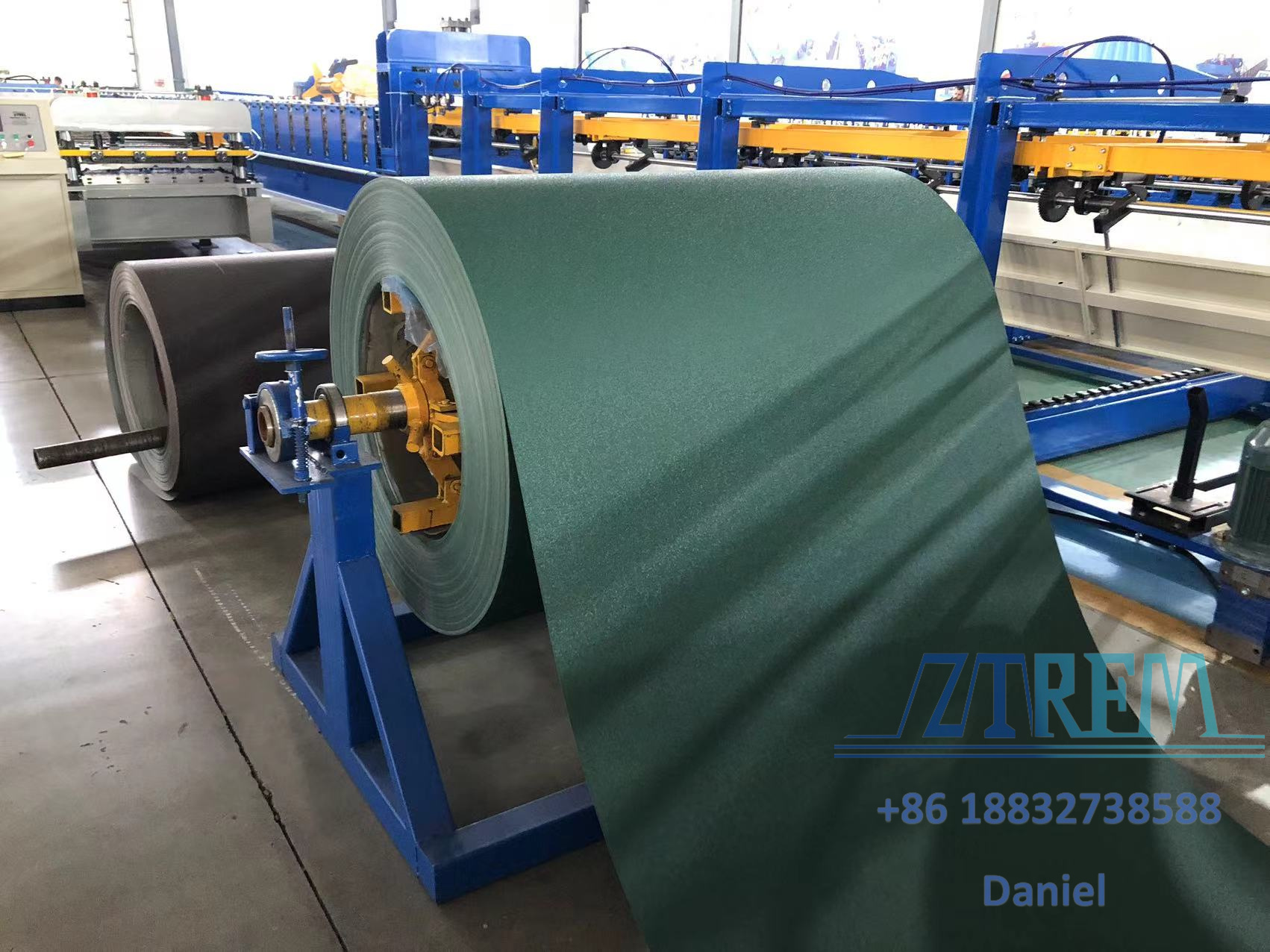

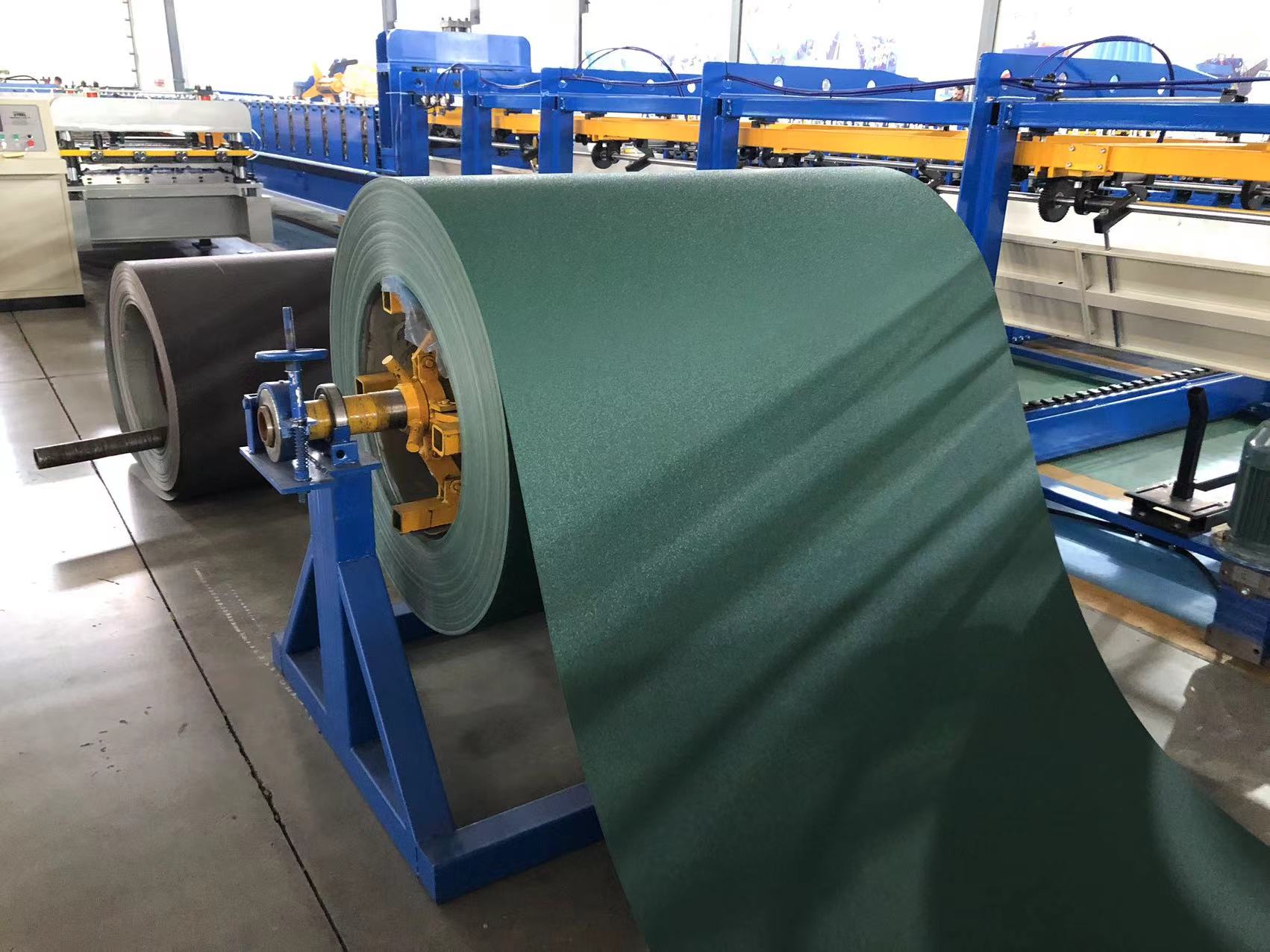

1. Manual Decoiler

Our manual unwinders are equipped with handwheels that can be operated by workers to assist in unwinding, and are additionally equipped with brakes to prevent slush and facilitate emergency braking and adjustment.

2. Feeding Device

Our Advantage:

1. With several support rollers, to feed the material more smoothly

2. With hand wheels to adjust the feeding size, more conveniently.

3. Up layer and down layer with manual cutter to cut feed material more easily.

4. Upper layer and down layer with two gears on the outside, so that the upper axis of each layer runs passively to actively, with

more power and faster.

3. Main forming machine

5. PLC Control System

4.Languages can be customized

6. Hydraulic Station + Accumulator

<p style="box-sizing: border-box; --tw-border-spacing-x: 0; --tw-border-spacing-y: 0; --tw-translate-x: 0; --tw-translate-y: 0; --tw-rotate: 0; --tw-skew-x: 0; --tw-skew-y: 0; --tw-scale-x: 1; --tw-scale-y: 1; --tw-pan-x: ; --tw-pan-y: ; --tw-pinch-zoom: ; --tw-scroll-snap-strictness: proximity; --tw-gradient-from-position: ; --tw-gradient-via-position: ; --tw-gradient-to-position: ; --tw-ordinal: ; --tw-slashed-zero: ; --tw-numeric-figure: ; --tw-numeric-spacing: ; --tw-numeric-fraction: ; --tw-ring-inset: ; --tw-ring-offset-width: 0px; --tw-ring-offset-color: #fff; --tw-ring-color: rgba(59, 130, 246, .5); --tw-ring-offset-shadow: 0 0 rgba(0,0,0,0); --tw-ring-shadow: 0 0 rgba(0,0,0,0); --tw-shadow: 0 0 rgba(0,0,0,0); --tw-shadow-colored: 0 0 rgba(0,0,0,0); --tw-blur: ; --tw-brightness: ; --tw-contrast: ; --tw-grayscale: ; --tw-hue-rotate: ; --tw-invert: ; --tw-saturate: ; --tw-sepia: ; --tw-drop-shadow: ; --tw-backdrop-blur: ; --tw-backdrop-brightness: ; --tw-backdrop-contrast: ; --tw-backdrop-grayscale: ; --tw-backdrop-hue-rot