Save space Save freight roll forming machine:Double layer roof sheet machine

Our double-layer roofing sheet machine is a machine that can produce two types of patterns, which can be customized according to customer requirements, better saving factory space and improving production diversity.

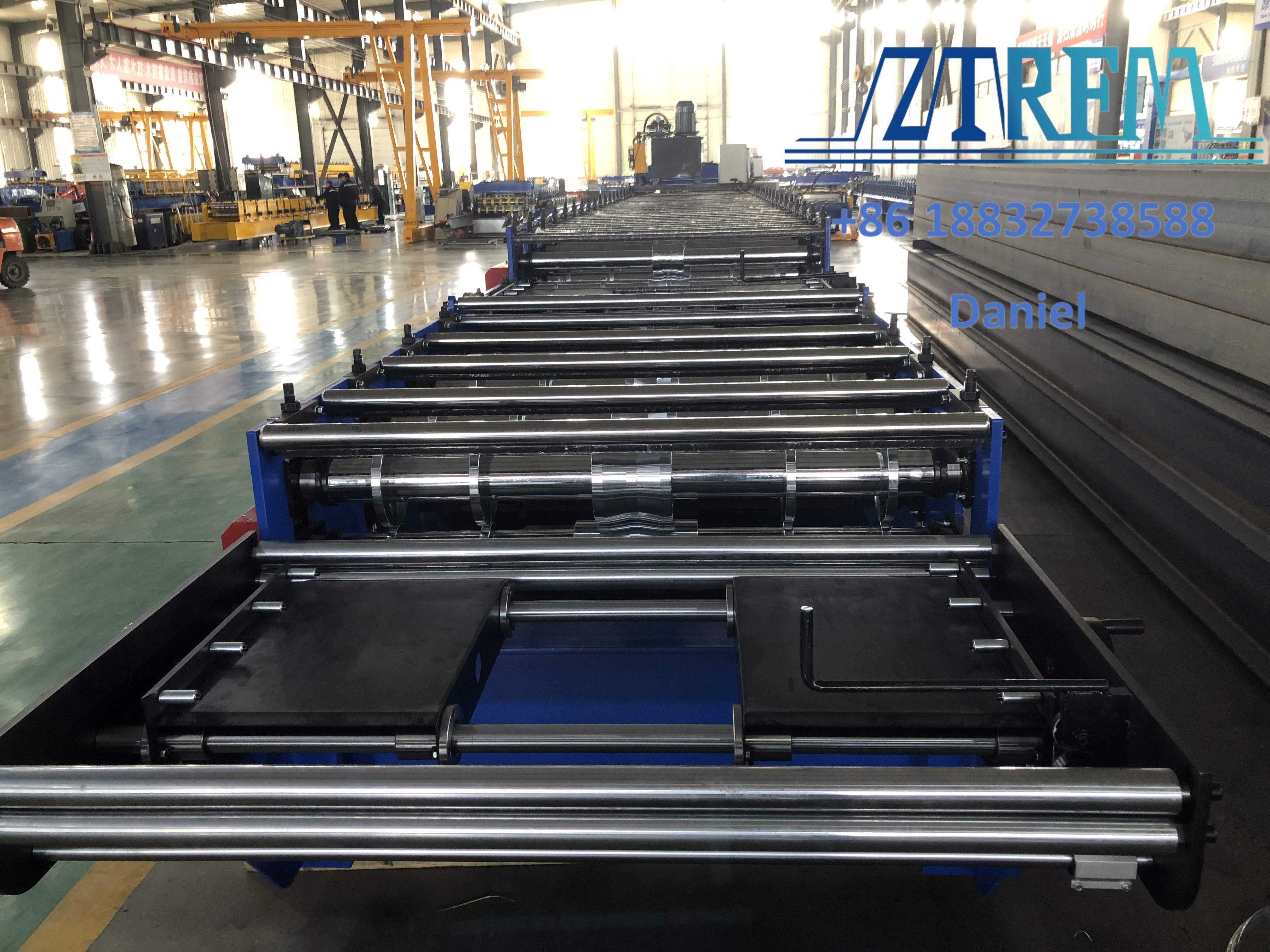

Let me show you our machine main part and parameters:

Our maachine combine from:

Decoiler---feeding device---Main roll forming machine(Double layer)--- hydraulic shearing system--- hydraulic station --- PLC control system --- Production receive table

About the decoiler ,

we has two kinds: Manual decoiler and hydraulic decoiler

Option 1: Manual decoiler:

Work type: passive type

Structure: Steel channel welded for the basic frame

usage:To support the coil and make the uncoiling

Loading capacity: 5 tons

Inner diameter: 450-550mm (manual adjustment)

Coil width: 1250mm

Brake system: manual brake

Option 2: Hydraulic decoiler

Decoiler type: Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

Carrying capacity :10 tons

Loading car capacity:10 tons

Max coil width: 1300 mm

Expand coil range: φ450-φ550 mm

Feeding speed: 0-45 m/min (adjustable)

Driving motor power: 7.5 kw

Hydraulic motor power: 3 kw

Structure: welding by the steel plates and profiled bar.

About main roll forming machine

The spacers and rollers advantage:

1. For all of our rollers, spacers and shafts, we all mark numbers on it, it’s very convenient for you to maintenance the machine in the future.

2. There is ball bearings inside the rollers, to make all the rollers run at same speed when machine is run.

3. Because the rollers inside with ball bearings, our rollers is bigger than others, so work speed is faster.

4. All rollers and spacers, we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories maybe use 1-2mm chrome coating.

We have a professionally designed clutch for the machine, which allows for manual adjustment of the clutch to complete production changes. There is also a wrench at the chain (when one layer is working, the other layer does not run, preventing the chain from idling and saving machine wear) and a tensioning device (adjusts the tightness of the chain and increases its service life).

<img alt='Double Layer roofing shee