Fully Automatic cable tray roll forming machine

Zhongtuo factory Automatic Steel Metal Cable Tray Cover Roll Forming Machine is a remarkable piece of equipment that operates with precision and efficiency. It starts by receiving the raw steel materials, carefully guiding them through its well-designed rollers. As the process unfolds, it smoothly bends and shapes the steel into the desired form of the cable tray cover, ensuring each curve and edge is perfectly crafted. It then precisely cuts the formed cover to the right length, ready for installation. This machine constantly monitors and adjusts its operations to maintain high quality output, making it an essential tool in the production of sturdy and reliable steel metal cable tray covers.

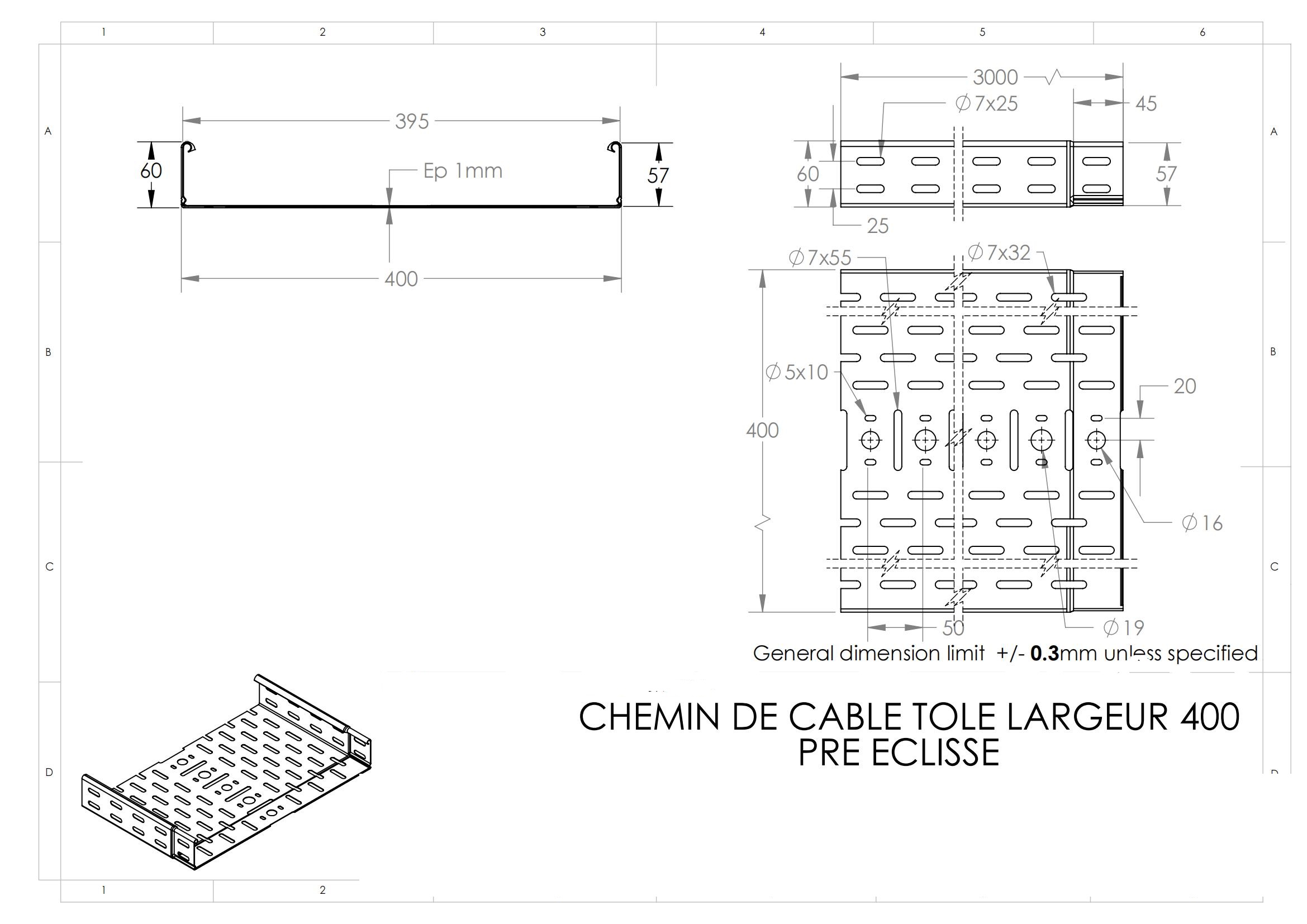

Final product of the cable tray roll forming machine

we adopt advanced technology to ensure no distortion, no damage to color painting, and accurate shaping.

Cut part of the Cable tray roll forming machine

1. The blade of the cable tray roll forming machine adopts high-quality Cr12

2. It is quenched twice to ensure sharp shearing and long lifetime.

3. It adopts an advanced hydraulic cutting system. No distortion and low noise.

Rollers of Cable tray roll forming machine

As the key part of the cable tray roll forming machine, the Rollers are made of high-quality Cr12 steel.

We develop new technology and more strict processing to make rollers.

Rollers become very accurate and durable, and their lifetime is longer than common machine.

The hydraulic station of the Cable tray roll forming machine

To improve stability and prolong life lifetime, this machine adopts a powerful 11 KW hydraulic station. it adopts the national standard motor.

Light duty cable tray rolling forming machine is designed to make the light duty cable trays in batch fully automatically. For the cable tray system is designed to carry electrical, data, and voice cables in horizontally and

vertically mounted light to medium duty commercial applications, up to a maximum width of 304mm. The LT12 / LT19 cable tray comprises of a flat sheet 3.0m in length, bent to a “U” profile - 12mm high (up to 76mm wide) or

19mm high (101mm to 304mm wide) to form a rigid channel like support, with Ø 7 x 28mm slotted perforations on the bottom of the tray to allow for air flow throughout the entire installation.